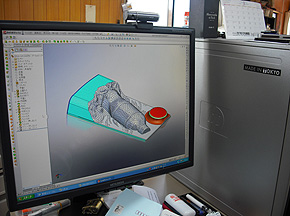

3D Program and CAD System

With the advanced 3D program and our own CAD/CAM network, we can speed up the process from designing to manufacturing and always produce stable processing techniques and products.

|

|

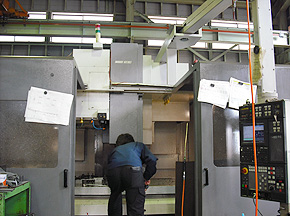

High-Performance Machining

We make full use of the high-speed rotating machinery boasting of a speed at 12000 r.p.m., one of the largest processing tables (2000 x 3000 in size) for portal and horizontal machining, and precision milling to process difficult-to-cut materials and high hardness substances with a high degree of accuracy.

|

|

|

|

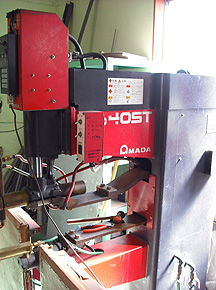

Wire-Electrical Discharge Machine

Wire cutting is less affected by the warps of materials and the stress strain characteristics, can work on ultrahard or hardened materials, and taper as well. By combining the machining process, the wire EDM guarantees beneficial effects on the compositely shaped processing.

|

|

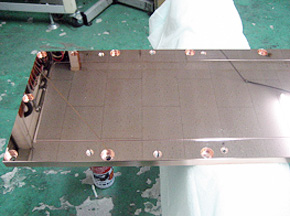

Processing Technology

As for the processing quality, machine performance is important. However, we also believe that only the processing technique, established by the many years of our experience and achievements, can maintain and improve technologies that create high-quality products. We offer our processing technique to various fields including the mold industry, the auto parts sector, and medical equipment business. Moreover, we manufacture large-size backing plates and the sputtering targets for electrically-conductive thin films.

|

|

|

|

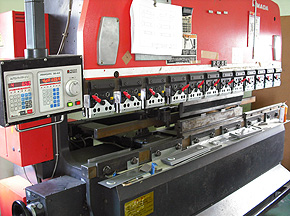

We process not only sheet metal by turret punch and bench press, but also we are involved in a wide range of metallic processing such as spot welding, semiautomatic welding, and argon arc welding.

|

|

|

|